ARMANDO CIMOLAI CENTRO SERVIZI SRL, San Quirino (PN), Italy

MAN Diesel SE, Deutschland

H. Cigielski, Poznan, Polen

Reinforcement of highly stressed machine bases

ThyssenKrupp MillServices & Systems GmbH, Oberhausen, Germany

New constructions and repairs

HOLTEC GmbH & Co. KG, Hellenthal, Germany

New constructions and repairs

Tidd Ross Todd (TRT) Ltd, Te Rapa, New Zealand

New constructions and repairs

Důlní strojírenská společnost spol.s r.o., Luční, Tschechische Republik

New constructions and repairs

Medag Stahlbau GmbH, Erbach, Deutschland

Treatment for elements of diesel engines

PROMOSTAL Sp. z o.o. Sp. k., Czarna Białostocka, Poland

Heckmann Metall- und Maschinenbau GmbH, Bremen, Germany

Levator Oy, Hanko, Finland

Used for new designs

Kocks Ardelt Kranbau GmbH, Eberswalde, Germany

Used for new designs and repairs of cranes for dry bulk handling

Sandvik Mining and Construction Oy

BAUER, Dubai, VAE

Use of HiFIT on repair

Ruukki Construction Oy, Helsinki, Finnland

Use of HiFIT on repair

Test bridge in Stöde, Sweden

Skanska MHT, Hisingsbron AB

Improvement of fatigue lifetime of columns. Lift Bridge Hisingsbron in Gothenburg (S).

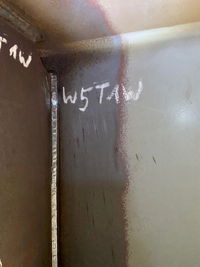

Treatment of the welds with the HiFIT process. (Weld transition and two-dimensional)

Maurer Söhne GmbH&Co KG, München, Germany

Zwahlen et Mayr S.A., Aigle, Switzerland

Intamin Amusement Rides

TKC d.o.o., Ljubljana, Slovenia

Spezialschweißen Anlagenbau Horst Zange, Nora, Germany

REPower Systems AG, Germany

K+S KALI GmbH, Zielitz, Germany

Used in maintenance and repair